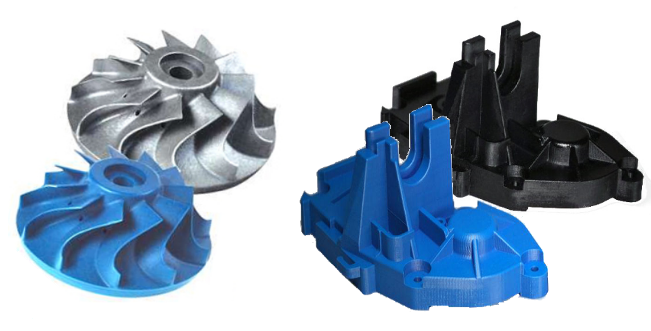

Rapid prototyping makes it possible for customers turning their great ideas into successful products much faster than before. First, we would convert your drawings to a 3D model, get a wax pattern by 3D printing, and then we get the raw casting by investment casting process. Finally, the casting would be CNC machined as your requirement. Using 3D printing rapid prototyping saves considerable time and investment in tooling for production,especially for small order.

Main Advantage Of Rapid Manufacturing:

1. No tooling costs

2. Short lead time

3. No need for stock

4. Optimize design without retooling

5. Narrow the gap between prototype and production