Side mount components are essential parts in various mechanical and structural systems, often used to provide support, alignment, or connection points. Precision casting, or investment casting, is an excellent method for manufacturing these components due to its ability to produce complex shapes with high accuracy and excellent surface finish. This guide outlines the steps to prepare for the precision casting of a side mount upper component.

Step 1: Design and Engineering

- Define Functional Requirements: Determine the load-bearing capacity, alignment needs, and environmental conditions the side mount upper will face.

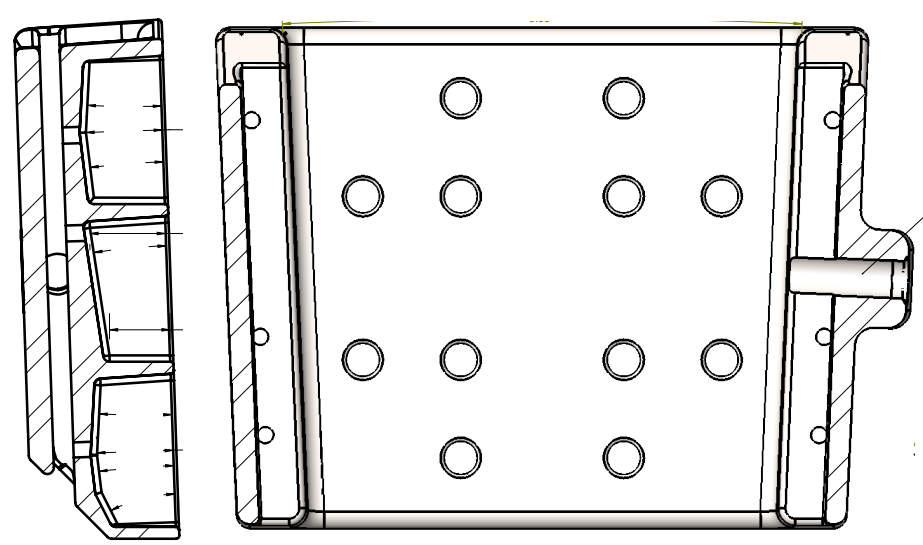

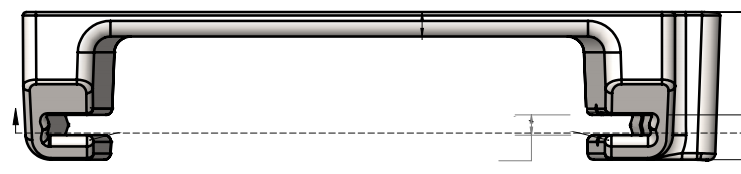

- Create a 3D CAD Model: Design the component with precise dimensions, including mounting holes, connection points, and any intricate features.

- Optimize for Casting: Incorporate draft angles, fillets, and machining allowances to ensure the design is castable and meets performance standards.

Step 2: Material Selection

- Choose the Right Alloy: Select a steel or stainless steel alloy that offers the necessary strength, durability, and corrosion resistance (e.g., 4140 steel for high strength or 304 stainless steel for corrosion resistance).

- Verify Material Properties: Ensure the alloy is suitable for precision casting and can withstand the operating conditions of the application.

Step 3: Pattern and Mold Preparation

- Fabricate a Wax Pattern: Use injection molding or 3D printing to create a precise wax replica of the side mount upper.

- Assemble the Pattern Cluster: Attach multiple wax patterns to a central sprue to enable batch production.

- Build the Ceramic Shell: Dip the cluster into a ceramic slurry and coat it with refractory sand. Repeat the process to create a thick, heat-resistant shell.

- Cure and Dewax: Allow the ceramic shell to harden, then melt out the wax to leave a hollow cavity for casting.

Step 4: Casting Process

- Melt the Alloy: Heat the selected steel or stainless steel alloy in a furnace to the required pouring temperature.

- Pour the Molten Metal: Carefully pour the molten alloy into the preheated ceramic mold, ensuring it fills all intricate details of the side mount upper.

- Control Cooling: Allow the mold to cool gradually to minimize internal stresses and prevent defects.

Step 5: Post-Casting Operations

- Remove the Ceramic Shell: Break away the ceramic mold to reveal the raw casting.

- Cut and Separate: Detach individual side mount upper components from the cluster using cutting tools.

- Clean and Finish: Remove any residual ceramic material and perform surface finishing, such as grinding or polishing, to achieve the desired surface quality.

- Inspect for Defects: Use non-destructive testing methods (e.g., X-ray or ultrasonic testing) to ensure the components are free of flaws.

Step 6: Machining and Assembly

- Machine Critical Features: Perform precision machining on mounting holes, connection points, and other critical areas to meet tight tolerances.

- Heat Treatment (if required): Apply heat treatment to enhance the mechanical properties of the side mount upper.

- Assemble and Test: Integrate the side mount upper into the final assembly and conduct functional tests to ensure it meets performance standards.

Conclusion

Precision casting is a highly effective method for producing side mount upper components with complex geometries and exceptional performance characteristics. By following this guide, you can ensure the production of high-quality components that meet the demands of your application. Collaboration with experienced foundries and meticulous attention to detail will further enhance the success of your casting project.