A corkscrew is a small yet intricate tool that requires precision, strength, and durability. Steel precision casting, or investment casting, is an excellent method for producing corkscrews with complex shapes and fine details. This guide outlines the key steps to prepare for the steel precision casting of a corkscrew, ensuring a high-quality and functional final product.

Step 1: Design and Prototyping

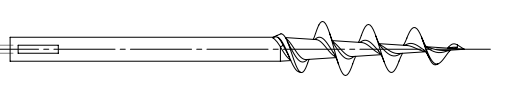

- Sketch the Corkscrew Design: Start with a detailed sketch, focusing on the spiral worm, handle, and lever (if applicable).

- Create a 3D Model: Use CAD software to design the corkscrew, ensuring precise dimensions and smooth curves for the spiral.

- Simulate the Casting Process: Run simulations to identify potential issues like air pockets or weak spots in the design.

Step 2: Material Selection

- Choose a Durable Steel Alloy: Opt for a high-strength, corrosion-resistant steel alloy, such as 420 stainless steel, to ensure the corkscrew can withstand repeated use.

- Verify Compatibility: Ensure the alloy is suitable for precision casting and can achieve the required sharpness and strength for the spiral.

Step 3: Pattern and Mold Creation

- Produce a Wax Pattern: Create a wax replica of the corkscrew using injection molding or 3D printing.

- Build the Ceramic Shell: Dip the wax pattern into a ceramic slurry and coat it with refractory sand. Repeat the process to form a thick, heat-resistant shell.

- Cure and Prepare the Mold: Allow the ceramic shell to harden, then melt out the wax to leave a hollow cavity for the molten steel.

Step 4: Casting the Corkscrew

- Melt the Steel: Heat the steel alloy in a furnace until it reaches the optimal pouring temperature.

- Pour the Molten Steel: Carefully fill the ceramic mold with molten steel, ensuring it flows into all fine details of the spiral and handle.

- Cool and Solidify: Let the mold cool slowly to prevent defects and ensure the steel sets correctly.

Step 5: Finishing and Assembly

- Remove the Ceramic Shell: Break away the ceramic mold to reveal the raw steel corkscrew.

- Clean and Polish: Remove any residual ceramic material and polish the corkscrew for a smooth, functional finish.

- Sharpen the Spiral: Use precision grinding to sharpen the spiral for optimal cork-pulling performance.

- Inspect for Quality: Check the corkscrew for defects and ensure it meets design specifications.

Conclusion

Producing a corkscrew through steel precision casting combines artistry and engineering. By following these steps, you can create a durable, high-quality corkscrew that is both functional and visually appealing. Attention to detail and collaboration with experienced foundries will ensure a successful casting process.